Design and manufacturing project - what you need to do:

50% of your final grade

As part of the Controlled Assessment component of the course, you will be required to complete a design and manufacturing Project. This project is worth 50% of your final qualification.

You will work through the process of:

- Identifying a design problem.

- Research and exploring solutions.

- Developing ideas.

- Modelling potential solutions.

- Manufacturing a final prototype.

- Evaluating the final prototype.

You will be assessed on how well you demonstrate the following learning outcomes:

| Design opportunity • Identify and analyse the design problem or opportunity. • Develop a clear design brief. Research and analysis • Conduct research that connects directly to the problem. • Analyse existing products and market needs. Specification • Write a detailed specification for your solution. | 10 marks |

| Concepts and analysis • Create and analyse concept sketches using freehand techniques. • Communicate your ideas with clear annotations. | 15 marks |

| Development of concepts • Develop your design using sketches and CAD. • Analyse how the design could perform better, considering function, size, ergonomics, safety, sustainability, etc. Modelling and testing • Build and test physical models to see if your solution works. • Modify your designs as necessary based on testing. Drawings for manufacture • Create scaled working drawings for your final product. | 25 marks |

| Manufacture • Manufacture a prototype that meets your design specifications. • Choose a range of appropriate materials. • Demonstrate manufacturing skills and attention to detail. | 40 marks |

| Evaluation • Test your prototype and write a reflective evaluation of its effectiveness. • Evaluate your prototype against your specification. • Suggest how to modify or improve the prototype. | 10 marks |

| TOTAL | 100 marks |

There are three pathways depending on which option you have chosen:

- Option A: Electronic and Microelectronic Control Systems; or

- Option B: Mechanical and Pneumatic Control Systems; or

- Option C: Product Design

Option A and B have been combined into a Systems pathway and Option C is the Product Design pathway

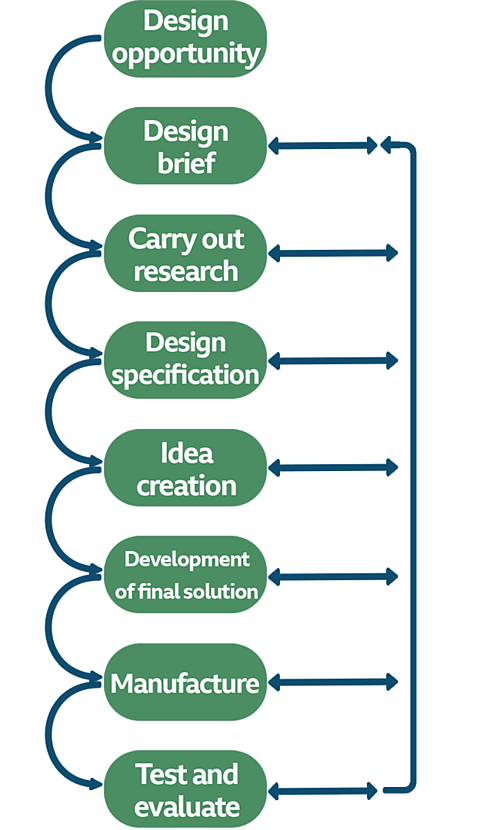

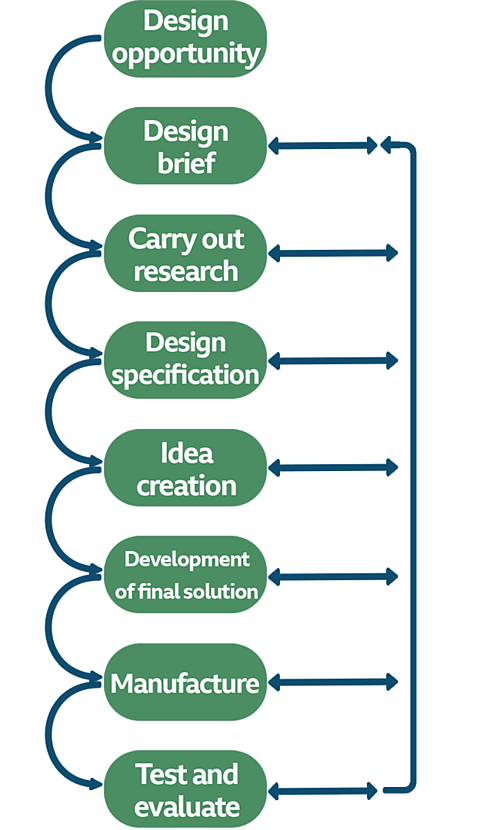

What are the stages of the design process?

A quick overview of the design process

The design process provides us with a series of important stages during the design and development of a product or solution. This involves exploring, creating, and evaluating ideas to develop a product, to solve a specific problem or need.The process can also be considered as a design cycle. This is due to the fact that the designer should constantly evaluate and improve their design ideas repeatedly until a robust solution is developed.

The design process also isn’t exactly linear, meaning that it doesn’t have to be completed in a specific order. However, each step still plays a very important role in the process as a whole.

Normally, the process will start with a design opportunity. This could come from a client asking for a certain product to be manufactured, or even the engineer themselves spotting a gap in the market or an unfulfilled need.

Research is a very important stage in the design process. Research will involve looking closely at the design opportunity to clarify exactly what the client needs, or what exactly is the perceived gap in the market.Research will also help gain new knowledge into areas that will help design the solution.Some example areas of research may include: analysis of similar solutions, investigation of suitable materials, consideration of suitable manufacturing processes.

Once you have completed your research, the next stage should be to form a design brief.

A design brief is a short outline of the key details of a design project, including the goals, deliverables, and even a visual direction. It can then be used as a reference throughout the rest of the process.

The next stage of development is completing a design specification. This should be a detailed list of requirements for your design. It should also list the issues that your design plans to address.

Some examples of what should be included in your design specification are: size, materials, cost, operation, appearance/aesthetics.You can then reference back to your design specification throughout the rest of the design process.

The next stage of the design process is idea generation. At this point in the process you can come up with your possible designs/solutions to the initial design brief.This should be done while referencing your design specification and the completed research throughout. A range of different designs developed using sketches and drawings with annotations will help you choose the best solutions.

Once you have completed the idea generation stage you will then have to decide on your final design. This should be based on an idea you have selected from your generated ideas.You might create a model to help refine how your design looks and operates. Models can be made from card or cheaper woods. Models can be tested to find design refinements.Working drawings should be made either by hand or using computer aided design (CAD) at this stage. Accurate dimensions and details of materials should be included to help manufacture your developed design idea.

The next stage in the process is manufacture. Manufacture will use the information in your working drawing and the tools, processes, and materials available in your Technology and Design workshop.

We all love coming up with ideas and solutions to problems, but if we do not carefully consider our approach to the development of the solution, what we manufacture may not meet the client’s needs.

The design process provides us with a series of important stages during the design and development of a solution.

Note:

The order of these stages is not fixed and will change depending on the design opportunity.

The process is often considered as a design cycle. The designer evaluates and improves their design ideas repeatedly until a solution is developed.

The stages of the design process

Design opportunity

Design opportunities arise out of real-life situations. These can be a problem that already exists or a new idea to deal with a situation.

The designers will set out to solve a problem or create a solution that meets the needs identified in the design opportunity.

Design brief

This is a short statement that outlines the problem to be solved. The designer will use information in the design brief to carry out further research and develop possible solutions.

Research

Research will involve looking closely at the design opportunity to clarify exactly what the client requires.

Research will also help gain new knowledge into areas that will help design the solution.

Areas of research may include

analysis of similar solutions

investigation of suitable materials

consideration of suitable manufacturing processes

Design specification

A specification will contain, in detail, the requirements of a developed solution. It is a list of the things that a product needs to address.

It can include some or all the following: size, materials, cost, operation, and appearance or aesthetics

Information in the specification will be used to help develop possible solutions.

Idea generation

Possible design ideas/solutions for the design brief will be generated based on your research and specification. Make sure you combine your own ideas with information from your research.

A range of different designs developed using sketches and drawings with annotations will help you choose the best solutions.

Development of final solution

The development of your solution will be based on an idea you have selected from your generated ideas.

You might create a model to help refine how your design looks and operates. Models can be made from card or cheaper woods. Models can be tested to find design refinements.

Working drawings should be made either by hand or using computer aided design (CAD) at this stage. Accurate dimensions and details of materials should be included to help manufacture your developed design idea.

Manufacture

Manufacture will use the information in your working drawing and the tools, processes, and materials available in your Technology and Design workshop.

You must learn how to use the tools and machines safely before manufacturing your product.

Test and evaluate

Your finally manufactured design solution will be tested on how it meets the design specification.

Ask questions like:

- How well does it function?

- Does it work reliably?

- Can it be used safely?

- What modifications would you make to your design?

Test yourself

Which stage of the design process is being described?

1. Alex is having trouble keeping her mobile telephone safe when riding on her mountain bike.

Design opportunity

2. Design a phone holder for use on a bicycle.

Design brief

3. Consideration of mobile phone holders on the market. Investigation of possible materials.

Research

4. The developed mobile phone holder should:

- hold one phone securely,

- be made of plastic,

- allow the phone to be used while holding the phone,

- be attractive to teenage phone users.

Design specification

5. Sketches of possible solutions with annotations.

Ideas generation

6. Working drawings with dimensions

Development of final solution

7. Use of a workshop including materials, tools, and resources.

Manufacture

8. Consideration of how well the manufactured solution meets the design specification

Test and evaluate

Further study

Systems pathway

Option A: Electronic and Microelectronic Control Systems or Option B: Mechanical and Pneumatic Control Systems

Product design pathway

Option C: Product Design