There are a number of different ways to cut metal and most designs will require a combination of approaches.

But before we get started, here are some of the things you might need:

A metal sheet with your design marked out

A pillar drill

A range of files

Emery cloth

Hacksaw

And an apron and goggles.

There are a range of hands-on methods for cutting metal and getting the result you need.

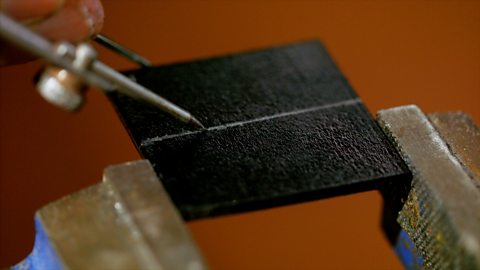

To make straight cuts, clamp your metal piece in a vice and use a hacksaw.

If your metal is thinner than 3mm you could also use a brake press guillotine or a sheet metal guillotine.

Most curves can be cut by making a series of straight cuts using a hacksaw and filing to the curve.

It can also speed up the process to drill a series of small holes along the curve before cutting and filing.

With all of these techniques, it's a good idea to leave a small amount of material outside the cutting line, about half a millimetre or so. Then you can file up to your mark using a range of files.

Circular holes should be made using a pillar drill, unless you're using thin sheet metal to drill circular holes up to 30mm in diameter. Then you'll need to use a step drill for accuracy and to stop the metal snagging or tearing.

Edges are shaped and flattened by cross filing, smoothed by draw filing and softened using an emery cloth.

A CNC plasma cutter is a great tool for cutting accurate and repeated shapes. It will have to be pre-programmed with your design using a 2D CAD application.

For this approach you don't need to mark your metal first. The computer will direct the plasma cutter to follow the programmed design.

Video summary

This short film explains the different ways to cut metal, depending on your design.

There are a range of hands-on methods for cutting metal and getting the result you need. This short film runs through a few of the most common.

Teacher Notes

Points for discussion

Discuss any other equipment which could be used to cut metal (and when it might be preferable to use these methods), for example:

- Sheet metal guillotine

- Nibbler

- Hand-held grinder/cutting wheel

- Abrasive wheel

Discuss the affect of using different grades of file, for example first cut, second cut.

Discuss the use of different shapes of file, for example square, half-round, round, triangular, for different shapes.

Discuss the different types of blade to be used for different thicknesses of metal, for example teeth per inch, or which is better, a hacksaw or junior hacksaw.

Discuss issues related to quality control – when is an item good enough/finished?

Discuss how to fix the component correctly in the vice to avoid excessive or wasteful vibration and noise.

Suggested activities

This activity can be fitted into any course of study which involves the manufacture of metal components, for example:

- Blades and tangs for garden tools

- Making a bottle-opener or multi-tool blade from steel or aluminium flat bar

- Manufacture of a wide variety of components for KS4 Iterative design and build projects

- Making a brass ‘net’ to be folded into a candle stand

- Cutting a shape to be made into a pendant or bag tag.

Suitable for teaching design and technology (D&T) at KS3/KS4 in England, Wales and Northern Ireland, and 3rd/4th levels in Scotland.

Marking shapes on metal. video

This short film explains how to mark out a design on metal before you begin cutting.

Drape forming. video

This short film explains the process of drape forming, which is used to create curved or more complex shapes out of plastic.

Line bending. video

This short film explains the process of line bending, which is a technique used to make precise folds in plastic components.