Traditional methods of production involve drawing designs by hand, creating a number of prototypes and using humans to manually produce goods or operate machinery. Some products still benefit from these methods of production, such as those with a reputation or tradition for being hand made.

However new methods of CAD and CAM offer the benefits of being cheaper, quicker and more efficient.

Computer aided design

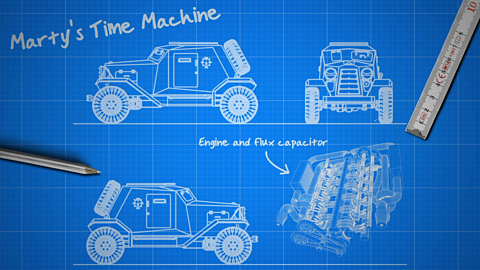

Computer Aided Design (CAD)the use of computers and software to design new products drawing allows components to be manufactured using Computer Aided Manufacture (CAM)using computers that control machines to produce goods.. Computer aided manufacture is very fast and accurate and requires less human intervention.

ANIMATION SEQUENCE

JOE

Hello and welcome to Tech Bitez. We have a jam packed episode in store for you today.We are finally ready to talk about manufacturing our product.

I am gonna take you step by stepon how I vacuum formed, cut, soldered and sanded this amazing product to life.

SANDY

Wait a minute. Are you planning to do all the manufacturing by hand?

JOE

Well, I’m hardly gonna use my feet.

SANDY

Oh, Joe. You aren't the sharpest tool in the workshop, are you? Like how long did it take you to manufacture the prototype?

JOE

Only like a week?

SANDY

And how many units are you looking to produce? Exactly. It could be your full time job, and you would still only produce two or three a month. I'm just assuming that you were off sick whenever I was teaching CAM at school.

JOE

Yeah, sure. Let’s just assume that.Suppose you're not up for a wee recap, are you?

SANDY

Fine.

ANIMATION SEQUENCE

SANDY

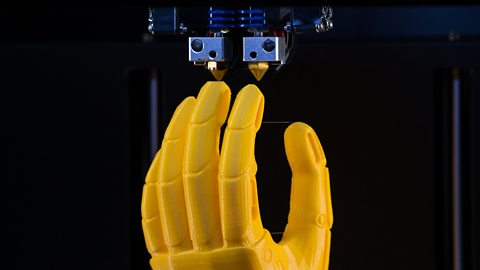

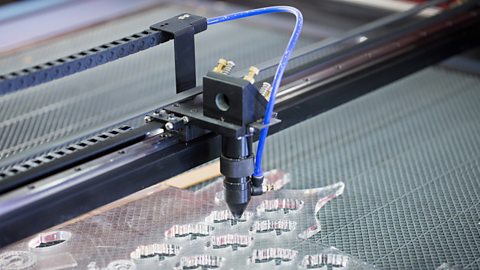

Computer aided manufacture CAM. Involves using computers to control machines to undertake the production of goods.Some examples of different CAM machines are 3D printers, laser cutters, as well as different milling machines. There are a number of advantages to CAM. For example, it achieves a much faster and accurate production.Machines can constantly run on repetitive tasks without getting bored or messing up.It's great for producing en masse or in the production line. Lastly, there is also less wasted material which should help keep your costs down.

JOE

That sounds great. There's got to be some sort of downside to, right?

SANDY

See, there you go, An actually useful question. There are also some disadvantages to using CAM. For example, the machines themselves can be quite expensive.It can also be quite labour intensive to set up. There is some downtime required for maintenance. And lastly, machines and computers can unexpectedly fail.

JOE

That sounds great. I'm just going to look up how much some of the machinery costs.Nope, handmade and bespoke it is. I'll just corner the hipster market.

Computer aided manufacture (CAM)

Computer aided manufacture (CAM) involves using computers to control machines during the production of goods. By using CAM, designs can be sent to CAM machines such as laser cutters, 3D printers and milling machines. Design files must first be drawn up using computer aided design (CAD) software.

laser cutting is when a high-powered laser is used to cut, etch or engrave a material.

Laser cutting is the use of a high-powered laser to cut, etch and engrave your material.

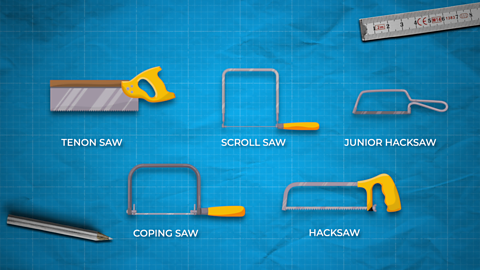

Before we get started here are a few things you might need:

A choice of materials for cutting

Your design

Access to a laser cutter and CAD software

Lasers cut by burning through the material and are incredibly precise.

They can be used on cardboard, paper, wood, foam, acrylic plastics as well as on some metals and glass.

It's useful to remember that it's possible to cut out and etch within the same project.

The first thing you need to do is to create your design.

Your CAD drawing has to be a vector file, which is different from an image file, as it can be resized without losing resolution and the lines remain smooth.

You can use 2D CAD programmes to make your vector file.

Lasers follow the design lines just like paths so they need to be perfectly smooth.

A CAD drawing usually consists of three colours.

The laser cutter can then be told to do different things with each colour.

The first colour should be used for the shapes that have to be cut out.

This is called 'vector cutting'.

The second colour should be used if you want to engrave sharp lines or outlines into the material.

This is called 'vector engraving'.

While it does cut into the material it doesn't cut all the way through.

The third colour is used for any designs you want to etch into the surface.

This is known as 'raster engraving' and works much like a regular laser printer.

For faster engraving, the laser cutter makes multiple passes across the surface of the material.

Once you've finalised your design, you will need to send it to the laser cutter.

There are two main variables to think about: the power of the laser and the speed it moves across the material.

The denser or thicker the material, the more power you will need to cut it.

The speed and power will also have an impact on how deep into the material the laser cuts.

With experience, you'll find which settings work best for different materials and thicknesses.

For now your teacher and the user guide for the machine will give you an idea of where to start.

So now the machine is set up, it's time to get cutting.

Laser cutters get extremely hot, so as it cuts, the machine cools the material by blowing compressed air.

Depending on the material, laser cutting can create smoke and fumes so it's important to make sure the extractor hood is turned on.

Watching the laser cutter bringing your design to life is the best bit, so enjoy it!

Laser cutters are incredibly precise, so the final product or component needs very little finishing.

Image caption, 3D printed model of a hand

Image caption, A laser cutter

Image caption, A milling machine

1 of 3

Advantages and disadvantages of CAM

Using computer aided manufacture (CAM) comes with some advantages and disadvantages:

| Advantages | Disadvantages |

|---|---|

| Machines can run 24/7 | The machines are expensive to set up |

| Produces products that are identical – accuracy | Computers and machines can fail |

| Less material is wasted | Engineers need to be highly skilled |

More on Manufacturing

Find out more by working through a topic

- count1 of 4

- count2 of 4

- count3 of 4